-

Bruno est né.Merci pour votre aide et votre soutien continus pour nous fournir des produits de haute qualité et abordables.

Bruno est né.Merci pour votre aide et votre soutien continus pour nous fournir des produits de haute qualité et abordables. -

Ehsan Salmari est décédé.Une réponse rapide et une attitude professionnelle facilitent notre coopération.

Ehsan Salmari est décédé.Une réponse rapide et une attitude professionnelle facilitent notre coopération.

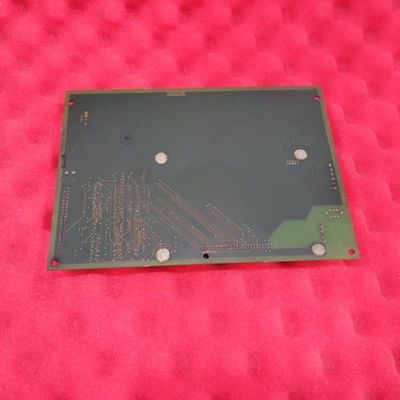

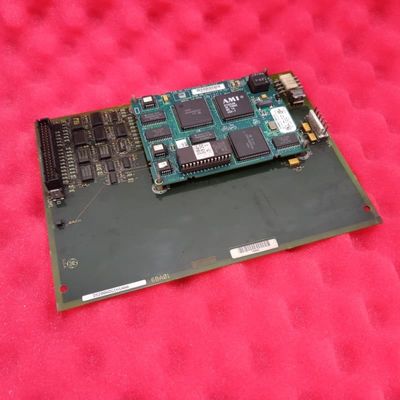

GE DS200ADGIH1A Carte d'interface auxiliaire Mark V 100mm x 200mm

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Nom | GE DS200ADGIH1A MARK V CARTE D'INTERFACE AUXILIAIRE | ID de produit | La valeur de l'échantillon doit être la même que celle de l'échantillon. |

|---|---|---|---|

| Série | Mark V | Largeur nette du produit | 100 mm |

| Hauteur nette du produit | 200 mm | Profondeur / longueur nette du produit | 330 mm |

| Garantie | 1 an | Poids net du produit | 2kg |

| Mettre en évidence | Carte d'interface GE Mark V,Carte auxiliaire de contrôle de turbine,Carte d'interface GE DS200ADGIH1A |

||

| Attribut | Valeur |

|---|---|

| Nom | GE DS200ADGIH1A Mark V Carte d'interface auxiliaire |

| ID du produit | DS200ADGIH1A |

| Série | Mark V |

| Garantie | 1 an |

| Dimensions (L × H × P) | 100mm × 200mm × 330mm |

| Poids | 2kg |

Le GE DS200ADGIH1A est une carte d'interface auxiliaire dédiée, conçue exclusivement pour le système de contrôle Mark V de GE, largement utilisé dans les applications de contrôle de turbines à gaz, de turbines à vapeur et de générateurs. Sa fonction principale est de servir de pont entre le contrôleur principal du système Mark V et les appareils auxiliaires, facilitant la transmission fiable des signaux et l'intégration des composants périphériques dans la boucle de contrôle.

Conçue selon les normes industrielles de GE, elle prend en charge le traitement des signaux d'E/S auxiliaires, y compris le conditionnement, l'isolation et la conversion des signaux analogiques/numériques en formats compatibles avec l'unité de contrôle centrale du Mark V. Cela garantit une communication transparente entre les systèmes auxiliaires critiques et la logique de contrôle principale de la turbine/du générateur.

Physiquement, elle comporte des bornes, des connecteurs et éventuellement des indicateurs d'état étiquetés pour faciliter le câblage, le dépannage et les contrôles opérationnels en temps réel. L'installation nécessite un personnel qualifié pour suivre les directives du système Mark V afin de maintenir la compatibilité et la sécurité. En tant que composant d'interface auxiliaire clé, elle améliore la flexibilité du système Mark V, garantissant que toutes les fonctions auxiliaires s'alignent sur la stratégie de contrôle principale pour un fonctionnement stable et efficace de la turbine/du générateur.